Kushal Udhyog

Kushal Udhyog manufactures abrasive blasting cabinets that facilitates

blast cleaning operation within a confined area. Abrasive particles issued

out of blast gun strikes the work surface placed inside the cabinet. The split

abrasive is recovered and re-circulated while the dust and the debris are

separated from the system. Exhaust air to the atmosphere is clean and

pollution free. .

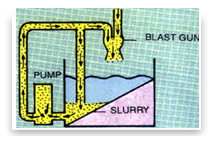

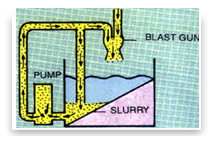

Wet Slurry Induction Principle :

Wet Slurry Induction Principle :

Water and abrasive slurry is sprayed

through the blast gun on the job for blast cleaning. The process is also

called wet blasting, liquid honing. and abrasive Slurry is sprayed through the

Blast Gun on the job for blast cleaning. The process is also Called

wet blasting, liquid honing.

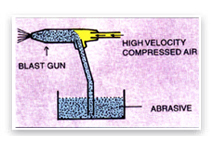

Suction

Blasting Cabinet Model KUS

Suction

Blasting Cabinet Model KUS

Works on the induction suction principle of abrasive blasting. A

partial vacuum created by high velocity airflow, draws the abrasive media form

the storage hopper into the blast gun.

Best suitable for blast cleaning, de-burring, de-scaling, removing thin

deposits on soft metallic parts and de-flashing of plastic and molded

components. It is also used to provide matt finish. The abrasives used are

medium to fine grade size bs mesh 25 or finer. It is also used for stress

relieving and shot peening for low medium preening intensity.

Three standard models are available namely, KUS 60/60, KUS 91/82, and KUS

120/90. Custom built cabinet size with a provision of atomization are also

available in order to suit individual customer requirements.

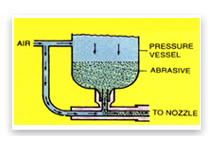

Pressure Blasting Cabinet Model KUP

Pressure Blasting Cabinet Model KUP

Works on the direct pressure principle of abrasive blasting. Abrasive

pressured in a pressure vessel and imparted forcefully to the nozzle. The

media attains high velocity and thus the blasting is intensive.

Abrasive particles acquire high velocity as compared to suction blasting,

giving high production output. It is best recommended for removing thick and

hard deposits, de-burring and de-flashing of hard metal parts using medium to

coarse grain of abrasive particles. Shot preening and stress relieving are

performed to medium and high peening intensity.

Three standard models are available namely, kup 91/82, and kup 120/90 and

kup 150/120. Custom built cabinet size with a provision of atomization are

also available in order to suit individual customer requirements

Wet

Blasting Cabinet Model KUW

Wet

Blasting Cabinet Model KUW

Works on the wet slurry induction principle of abrasive blasting. Water

and abrasive slurry is sprayed through the blast

gun on the job for blast cleaning. The process is also called wet blasting

or liquid honing.

The equipment uses fine to super fine abrasive. It is used to remove thin

deposits, scales, fine burrs from multi-tooth cutting tools, and for super

finishing of machined surfaces without damaging the sharp edges and

tolerances. The cabinet inside walls are zinc metallized to prevent the

equipment against corrosion.

Three standard models are available namely, KUW 60/60, KUW 91/82, and

KUW

120/90.

Abrasive Blasting Cabinets Standard Models :

|

Model

|

Suction Blasting |

Pressure Blasting |

Wet Blasting |

|

KUS-60/60 |

KUS-91/82 |

KUS-120/90 |

KUP 91/82 |

KUP 120/90 |

KUP 150/120 |

KUW 91/82 |

KUW 120/90 |

Working Chamber (mm)

Height

Width

Depth |

600

600

600 |

775

910

820 |

900

1200

900 |

775

910

820 |

900

1200

900 |

900

1500

1200 |

775

910

820 |

900

1200

900 |

|

Fan Motor |

0.5 HP |

1.0 HP |

1.5 HP |

1.0 HP |

1.0 HP |

1.5 HP |

0.5 HP |

1.0 HP |

|

Fan Capacity |

200 cfm |

400 cfm |

600 cfm |

500 cfm |

500 cfm |

800 cfm |

200 cfm |

400 cfm |

|

Filter Cloth |

1.0 sqm |

2.0 sqm |

4.0 sqm |

7.5 sqm |

7.5 sqm |

10 sqm |

- |

- |

|

Air Injector (mm) |

*2 / 3 |

*3 / 4 |

3 / *4 |

- |

- |

- |

2 / *3 |

*3 / 4 / *5.5 |

|

T.C.Nozzle (mm) |

*6 / 8 |

6 / *8 |

8 / *10 |

*5 |

*5 |

*5 |

*8 |

*8 |

|

Blast Hose (mm) |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

|

Air Consupmtion |

*21 cfm |

*25 cfm |

*45 cfm |

*56 cfm |

*56 cfm |

*56 cfm |

25 cfm |

25 cfm |

|

Air Compressor Required |

7.5 H.P. |

7.5 H.P. |

15.0 H.P. |

20.0 HP |

20.0 HP |

20.0 HP |

7.5 HP |

10.0 HP |

|

Abrasive Capacity |

1.0 cft |

1.0 cft |

1.5 cft |

1.0 cft |

1.5 cft |

1.5 cft |

1.5 cft |

1.5 cft |

Optional

Accessories For Abrasive Blasting Cabinets

Optional

Accessories For Abrasive Blasting Cabinets

Tumble Basket :

Timer controlled motorized tumble basket is installed on the side door of

the cabinet. It is used for automatic blast cleaning of smaller similar

components in a suitable batches.

Tumble basket is available in two sizes. Length mm / dia. Mm / load capacity

kg : 300/ 250 / 20 and 350 / 300 /25

Inside

Turn Table :

Inside

Turn Table :

Manual or motorized turn table is fixed on bearing inside the cabinet to

impart job rotation.

Standard turn table dia. (mm) and load capacity (kg)

500 / 50, 600 / 50 and 700 / 60

Work

Car With Turn Table And Mounted Track Extension :

Work

Car With Turn Table And Mounted Track Extension :

Track extension is provided inside and outside the cabinet for work

car movement. The work car is fitted with manual turn table so that job is

loaded and unloaded outside the cabinet.

Car with water wash pan : (for Wet Blasting

Cabinets Only)

Wet blasted components needs rinsing. Thus water wash pan is fixed outside the

cabinet with splash system outside the cabinet.

Water wash pan length approximately 1500 mm.

Work car length 500 mm, 600mm and 700 mm.

Standard turn table dia. (mm) and load capacity (kg)

500 / 50, 600 / 50 and 700 / 60

Kushal Udhyog manufactures abrasive blasting cabinets that facilitates

blast cleaning operation within a confined area. Abrasive particles issued

out of blast gun strikes the work surface placed inside the cabinet. The split

abrasive is recovered and re-circulated while the dust and the debris are

separated from the system. Exhaust air to the atmosphere is clean and

pollution free. .

Kushal Udhyog manufactures abrasive blasting cabinets that facilitates

blast cleaning operation within a confined area. Abrasive particles issued

out of blast gun strikes the work surface placed inside the cabinet. The split

abrasive is recovered and re-circulated while the dust and the debris are

separated from the system. Exhaust air to the atmosphere is clean and

pollution free. .

Direct Pressure Principle :

Direct Pressure Principle : Wet Slurry Induction Principle :

Wet Slurry Induction Principle :

Optional

Accessories For Abrasive Blasting Cabinets

Optional

Accessories For Abrasive Blasting Cabinets Inside

Turn Table :

Inside

Turn Table :

Work

Car With Turn Table And Mounted Track Extension :

Work

Car With Turn Table And Mounted Track Extension :