In these machines, abrasive blasting and abrasive recovery is simultaneous.

The spent abrasive is confined in a small vicinity on the job itself and the

same is pneumatically sucked and fed to abrasive storage for re-cycling.

In these machines, abrasive blasting and abrasive recovery is simultaneous.

The spent abrasive is confined in a small vicinity on the job itself and the

same is pneumatically sucked and fed to abrasive storage for re-cycling. Pneumatic suction of abrasive is affected by suction caused either with the help of compressed air or by vacuum pump or by electric motor drive blower. Various models are available to suit individual application.

1.)

Portable Mini Vaccum Blaster

1.)

Portable Mini Vaccum Blaster Model ‘KUV – 14P’ :

This is a very handy dust free portable vacuum cleaning machine. A light weight machine weighing only 3.7 kgs and can hold abrasive upto 1.7 kgs of metallic grit. It requires 40 to 60 cfm at 90 psi. It is mostly used for touch-up work on plain or curved surface for removal of rust / scale / paint. Fine abrasives like aluminium oxide, plastic grit or agro based abrasives is mostly used. In fact it is a very economical hand tool.

| Salient Features : |

||

| Light Weight | : | Easy To Handle |

| Flexible Blasting | : | Nozzle Can Be Positioned Overhead / Down Head Or Side Ways. |

| Ready To Use | : | Does Not Require Setting Time. |

| No Electric Connection | : | Needs Only Compressed Air. |

| Wide Pattern | : | Blasting Pattern Up To 30 Mm. |

| Multi Abrasive Choice | : | Light Weight Abrasives Of Finer Grades Are Usable. |

2.)

Portable Vaccum Blasting Equipment :

2.)

Portable Vaccum Blasting Equipment :

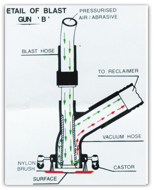

The vacuum blasting equipment operating principle is shown here in

diagrammatic cross section. The arrows marked in green indicates abrasive flow

that is pressure fed from the pressure vessel / abrasive tank (a) to the blast

gun (b) and it is vacuum recovered via vacuum hose to the reclaimer unit (c).

The gun body is specially designed to hold blast nozzle as well as the

recovery hose. A nylon brush surrounds the gun body to prevent the escape of

abrasive and dust. The blast gun remains in close touch with the surface to be

cleaned.

The reusable abrasive is air washed and sieved and returned to abrasive tank

(a) for reuse. Dust and debris are trapped by the cyclone (d) and dust

collector (e). Reverse air flow (vacuum) is created by compressed ‘air

ejector’ or by vacuum pump (f). The complete equipment is mounted on castors

which facilitate movement along the work site. Atomized gun maneuvering with

crawler unit (optional) can be provided on demand. However, this equipment is

not suitable for irregular and complex shaped surface profiles, until and

unless a special brush is developed.

The reusable abrasive is air washed and sieved and returned to abrasive tank

(a) for reuse. Dust and debris are trapped by the cyclone (d) and dust

collector (e). Reverse air flow (vacuum) is created by compressed ‘air

ejector’ or by vacuum pump (f). The complete equipment is mounted on castors

which facilitate movement along the work site. Atomized gun maneuvering with

crawler unit (optional) can be provided on demand. However, this equipment is

not suitable for irregular and complex shaped surface profiles, until and

unless a special brush is developed.

Technical Specifications :

| S.No. | Description | KUV – 15P | KUV – 15E |

| 1 | Main Feature | Pneumatic Recovery | Vacuum Pump Recovery |

| 2 | Overall Dimensions (mm) | 800 x 1100 x 2200 H | 800 x 2000 x 2200 H |

| 3 | Abrasive Tank Capacity | 42 Liters (1.5 cft) | 2 Litres (1.5 cft) |

| 4 | Storage Tank Capacity | 28 Litres (1.0 cft) | 28 Litres (1.0 cft) |

| 5 | T.C. Lined Blast Nozzle | 6 mm | 6 mm |

| 6 | Blast Hose Dia & Length | 19mm x 7.5 mtrs. | 19mm x 7.5 mtrs. |

| 7 | Suction Hose Dia. & Length | 38 mm x 8 mtrs. | 38 mm x 8 mtrs. |

| 8 | Dust Collector Hose | 75 mm x 1.5 mtrs. | 75 mm x 1.5 mtrs |

| 9 | Recovery System | Air Injector | Vacuum Pump |

| 10 | Reclaimer Type | Cyclone & Vibrating Screen | Cyclone & Vibrating Screen |

| 11 | Dust Collector | S.S. Cartridge | Paper Cartridge |

| 12 |

Compressed Air Requirement |

290 cfm at 6.33 kg / Sq.Cm. | 68 cfm at 6.33 kg / Sq.Cm. |

| 13 | Electrical Load Required | NIL | 10.0 HP, 415V, 3P, 50 Hz |

| 14 | Recommended Abrasive | 16 to 36 BS MESH | 16 to 36 BS MESH |

| 15 |

Cleaning Rate Inlet Air Connection |

19 mm | 19 mm |

Silent

Features :

Silent

Features :